东华大学朱美芳院士团队潘绍武等:弹性应变传感纱线的互锁集成实现智能医疗服装的分布式检测

多点传感显著增强了可穿戴技术在健康检测中的准确性和完整性。然而,全身稳定的多点电子传感监测仍面临挑战。

近日,️东华大学朱美芳院士和潘绍武研究员等人在Science China Materials发表研究论文,通过弹性应变传感纱线的互锁集成技术,成功开发了一种新型的智能服装,实现了适用于智能医疗的分布式检测。

️本文要点

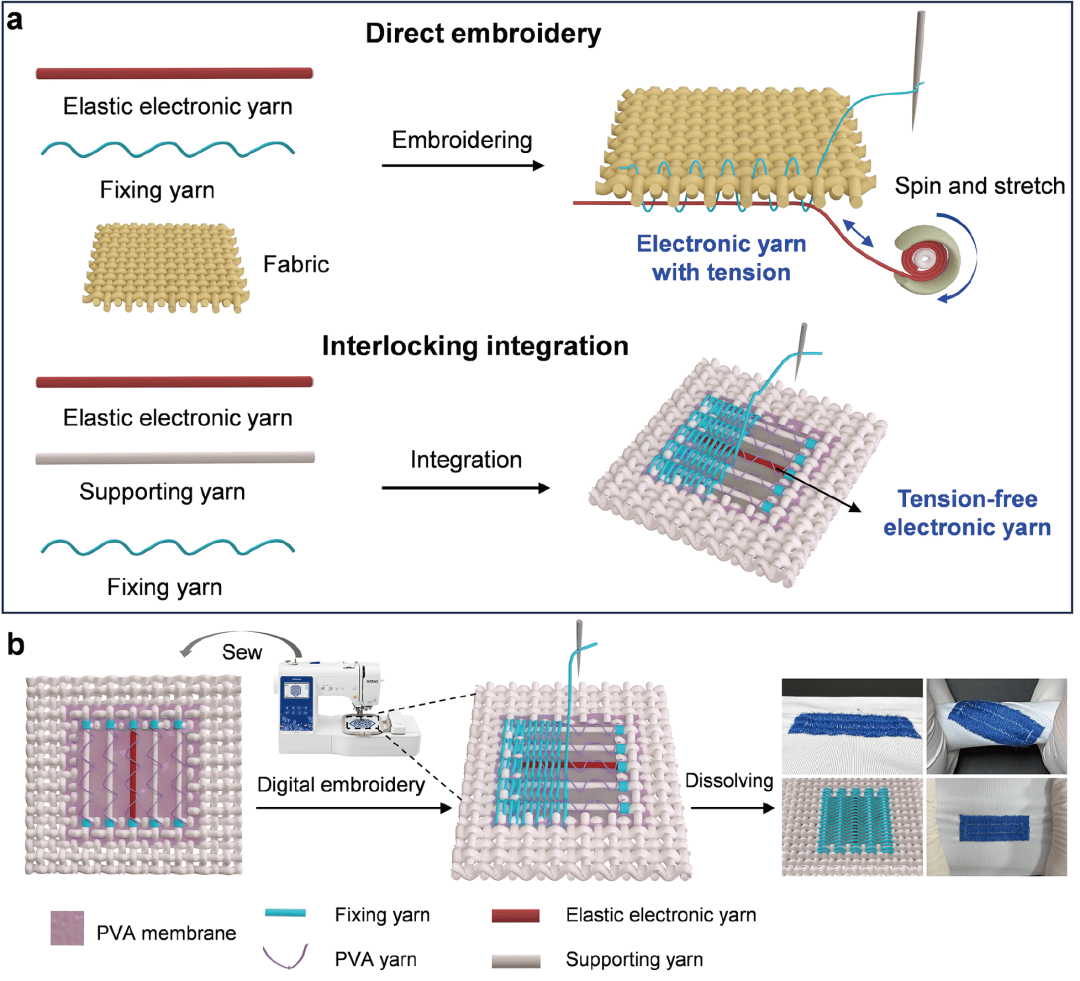

1) 这种服装中的弹性应变传感包覆纱线,拉伸率为170%,应变系数为414,通过无缝集成形成了稳固的传感器-服装互锁结构。集成传感纱线的织物具备良好的透气性、可洗涤性及耐磨性。

2) 开发了一种用于评估慢性阻塞性肺病的可穿戴呼吸监测带,其测量数据与商用便携设备相媲美。

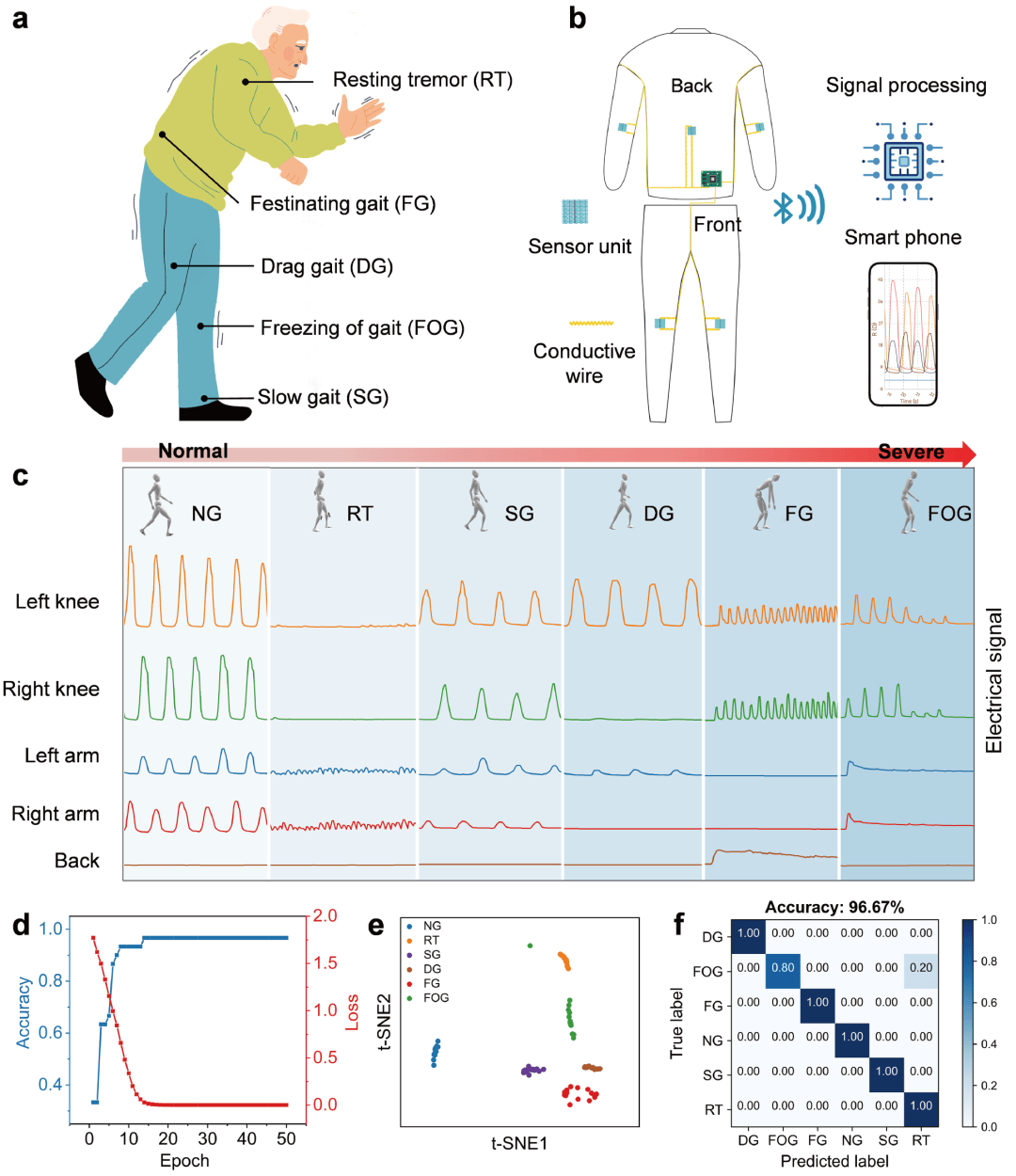

3) 研制了一种具备分布式检测能力的智能服装,能够有效识别帕金森病的运动症状,经深度学习算法验证,识别准确率高达96.67%。

这些研究成果表明智能分布式传感服装在可穿戴健康系统中的巨大潜力。

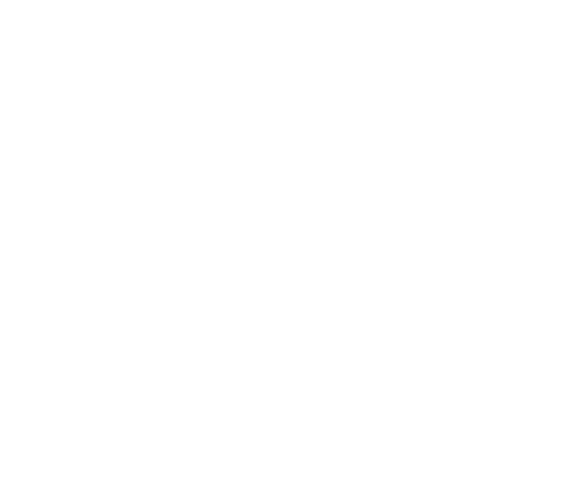

️Figure 1. Schematic diagram of distributed electronic yarn-based sensors integrated into clothing for wearable healthcare applications.

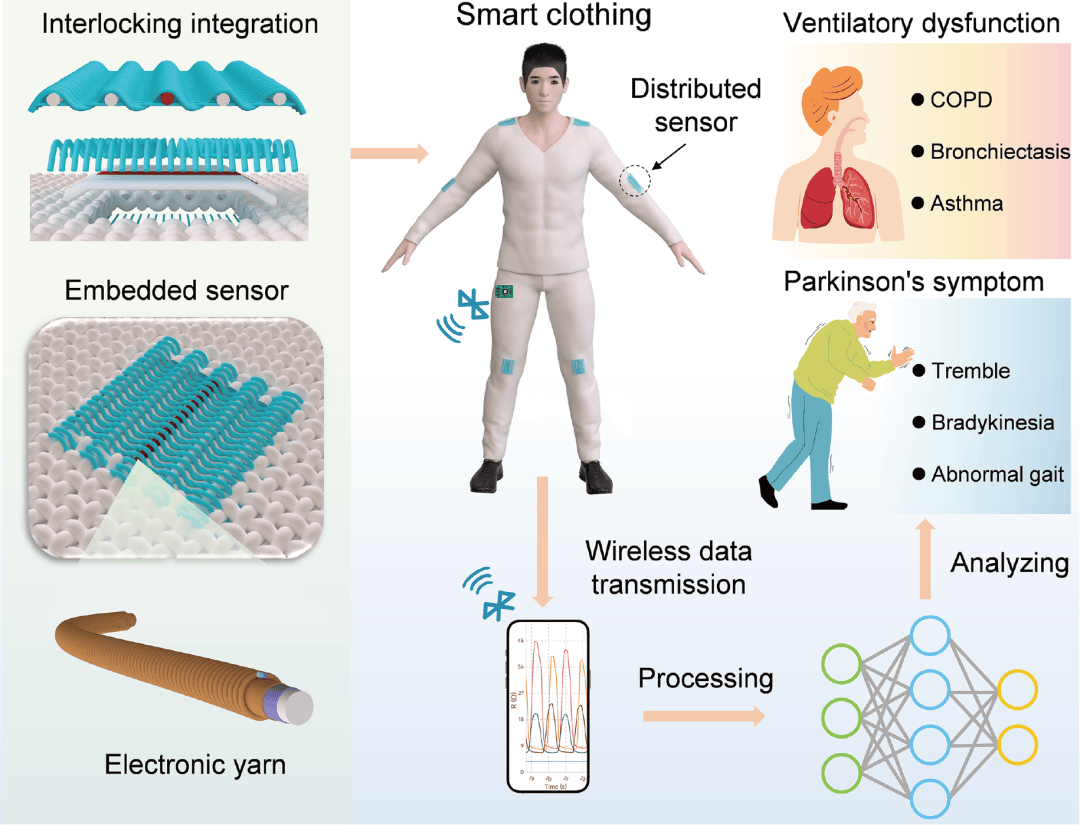

️Figure 2. Schematic diagram of the fabric sensor fabricated from electronic yarn. (a) Schematic comparison of two methods for fabricating fabric sensors, including the traditional embroider method (upper) and our proposed interlocking integration (bottom). (b) Preparation process of fabric sensor from elastic strain sensor yarns, involving sewing of the electronic yarn and digital embroidering patterns to form an interlocking structure; photographs of the resulting fabric sensor under mechanical deformations, including twisting and stretching.

️Figure 3. Morphology and performance of the fabric sensor made from strain sensor yarn. (a) Schematic illustration of the structure and sensing mechanism of the strain sensor yarn with (b) SEM images showing the inner (right) and outer (left) layers of a strain sensor yarn under tensile strains of 0% (top) and 50% (bottom). (c) Relative resistance changes of the strain sensor yarn at different tensile strains. (d) Durability of the strain sensor yarn under a tensile strain of 50% over 1000 cycles. (e) Comparison of gauge factor and working range between our strain sensor yarn and those reported in the literature for yarn-based sensors. (f) Performance of the strain sensor yarn-based fabric sensor after washing. (g) Performance of the fabric sensor after being abraded 100 times with sandpaper. (h) Comparison of water vapor permeability between the fabric sensor and commercial fabrics.

️Figure 4. Smart clothing with distributed sensors for monitoring Parkinson’s disease. (a) Schematic of the symptoms in Parkinson’s patients. (b) Schematic of sensor distribution in clothing and its signal processing and display. (c) Sensing signals of smart healthcare clothing detect simulated characteristic actions in Parkinson’s disease. (d) Accuracy and loss in 50 epochs. (e) Distribution of datasets in a 2D space. (f) Confusion matrix results for the six types of movements.

️【作者简介】

️Liang Wu (吴亮) is currently an MS candidate in the College of Materials Science and Engineering, Donghua University. He received his BS degree from Suzhou University of Science and Technology in 2022. His research interests include smart fibers and wearable electronics.

️Yong Wang (王勇) is currently a PhD candidate in the College of Materials Science and Engineering, Donghua University. He received his BS degree in condensed matter physics from Lanzhou University of Technology in 2024. His research interests include functional materials and wearable electronics.

️Shaowu Pan (潘绍武) is a professor at the School of Materials Science and Engineering, Donghua University. He received his PhD degree from Tongji University in 2015, with joint research experience at Fudan University. Afterward, he worked as a postdoctoral fellow at Nanyang Technological University in Singapore. His research interests include smart materials, flexible sensors, and fiber electronics.

️Meifang Zhu (朱美芳) obtained her PhD degree in materials science in 1999 from Donghua University (DHU, Shanghai). She is currently a professor at DHU and a member of the Chinese Academy of Science. Additionally, she is the director of the State Key Laboratory of Advanced Fiber Materials. Her research focuses on the fundamental chemistry, properties, and applications of fiber materials and organic/inorganic hybrid nanomaterials, with a particular emphasis on green energy, environmental sustainability, and healthcare.